Someone asked, students learn STEM in school, learn how to program and operate robots, learn how to build 3D models and use 3D printers to print real objects. What is the meaning and use of these learning in the real world?

The following examples can see evidence of technology application and improvement of life.

3D printing: tailor-made orthopedic models for patients

Orthopedic specialist Liao Jingle pointed out that the orthopedic bone model is made by traditional methods. The doctor confirms the cutting point by X-ray and visual inspection. After the operation, the patient needs to wear an external fixator for 6 to 12 months. The wound needs to be washed every day, and the length of hospital stay or Up to more than 200 days.

After the introduction of 3D printing technology, doctors can scan the patient’s bones by computer to calculate the cutting position, and then 3D print out the patient’s surgical bone model, insert the bone model into the real bone before the operation, and align it with the bone model. Position cutting to improve accuracy.

In addition, the doctor will use the method of “internal fixation” to fix the bones between the patient’s bones and muscles with steel plates and screws before removing the bone model. This new method eliminates the need for external fixation stents for patients, shortens the recovery time and eliminates the need for frequent wound washing. The number of hospital stays can be reduced from more than 200 days to 4 days. The application of STEM can relieve the patient’s skin and flesh pain, and also help. Society saves medical costs!

VR Virtual Reality: Simulating Aircraft Maintenance

PolyU uses VR (Virtual Reality) teaching system to assist teaching. The system can simulate scenes such as computer rooms, elevators and even aircraft maintenance, and project 3D images, so that students can learn about different mechanical systems and train safety awareness under the guidance of instructors.

Good news for patients with minimally invasive surgery with high-precision robotic arms

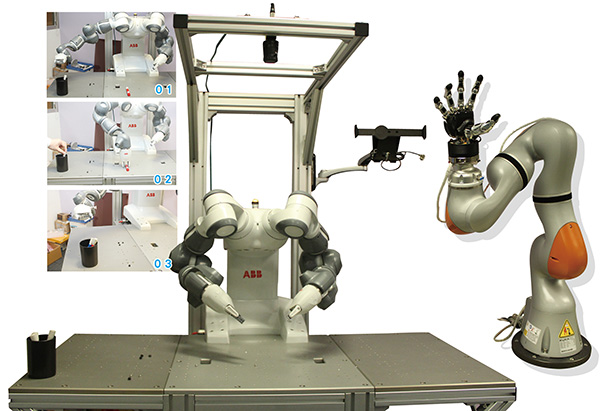

A team of senior engineers led by the Deputy Director of the Department of Industrial and Systems Engineering, Professor Rong Qiliang, and Professor Chongguang Yang, the Honorary Clinical Professor of the Department of Surgery at the Li Ka-shing Faculty of Medicine, the University of Hong Kong, successfully developed the world’s first built-in motor last year with up to ten freedoms of movement The new surgical robot system (Novel Surgical Robotic System-NSRS) with a high degree of robotic arm.

There is only one surgical robot system in the minimally invasive surgery market today. This system is not only very expensive, but also has many shortcomings, including the need to make multiple incisions (3 to 6) on the patient and lack of touch (strength) ) Feedback and bulky body, etc. In contrast, the new NSRS surgical robot system can enter the human body through a single small incision or through a natural cavity, and expand in the body to perform various surgical procedures.

The functions of NSRS cover all kinds of abdominal or pelvic surgery. The robotic arm can not only perform high-precision movements, but also provide highly sensitive tactile or force feedback, which is an important step in opening up the field of non-invasive surgery in the future.

Citation source: OpenSchool